Products

We offer a variety of solutions in the overhead & floor conveyor industry. Our products and solutions span a wide range of material handling operations such as parts handling. In addition to our standard conveyor systems, we can custom engineer material handling equipment for many unique applications. These systems include: Slat, Dual Strand & Roller Flight Chain Conveyors, Transfers, Turntables, Heavy Duty Belt & Roller Conveyors, Scrap & Recycling Conveyors, and Electrified Monorails.

Overhead Conveyors

Continuous Powered - Enclosed Track Overhead Conveyor

These systems utilize an enclosed steel track which guides the trolleys and protects them from direct contamination.

Applications include: finishing and processing systems, assembly operations, parts transfer, storage, over & under, delivery, etc.

A wide variety of part hooks, swivels, indexers, and custom designed carriers are available to handle your product.

Model Number

1500

2000

8000

All-Flex®

Chain Pitch

1-1/2″

2″

8″

6″

Max Trolley Load

50 lb

80 lb

75 lb

50 lb

Max Chain Pull

360 lb

720 lb

750 lb

600 lb

8000 Series

Continuous Powered - I-Beam Track Overhead Conveyors

True workhorses of industry, these medium and heavy duty overhead conveyors offer capacities ranging from 200 to 1,200+ lbs.

Applications typically include:

- large finishing and process systems,

- assembly operations,

- transfer, storage & delivery of heavy items.

For conveying medium to heavy parts over short or long distances, these conveyors provide maximum performance and reliability.

Model Number

3000

4000

6000

Chain Pitch

3″

4″

6″

Max Trolley Load

250 lb

500 lb

1200 lb

Max Chain Pull

1800 lb

4000 lb

6500 lb

Power & Free - Overhead Conveyors

Power & Free is a natural progression from continuous powered, overhead conveyors. These conveyors offer maximum cost effectiveness and flexibility in materials handling

For the first time within the 500 lb to 1000 lb load category, a predictable and positively powered system with “on-line” accumulation and switching capability is available to industry.

The AC 8500 Series is a system that will solve both simple and complex handing problems. It is possible to interconnect many operations within a plant, while simultaneously accommodating specific local process variations.

Allied’s Power & Free conveyors are readily adaptable to computerized operation, thereby permitting precise control throughout the entire materials handling system.

Larger capacity systems are also available.

- Accumulation centers as small as 8″

- Varying chain speeds to maximize flexibility

Model Number

3000

4000

6000

Chain Pitch

3″

4″

6″

Max Trolley Load

250 lb

500 lb

1200 lb

Max Chain Pull

1800 lb

4000 lb

6500 lb

Floor Conveyors

Continuous Powered

Design flexibility coupled with simple installation.

The 8000 Series provides proven performance in systems ranging from simple gravity flow to complex powered applications. The 8000 is a medium duty conveyor (750 lbs. chain pull capacity) that operates in an inverted mode.

An enclosed steel track protects and guides the chain assembly, eliminating the need for special wheel or roller turns. In addition to traditional conveying, applications include numerous special designs such as paint systems and assembly processes for maximum cleanliness and product accessibility.

Several other types of floor conveyors are also available, with varying capabilities to suit any need. (ex. In-Floor Drag, Towlines)

Model Number

8000

Chain Pitch

8″

Max Trolley Load

75 lb +

Max Chain Pull

750 lb

Special Applications / Engineered Systems

Power & Free System

Power & Free System

Truck Frame Manufacturing – Frame Transfer Conveyor

This Power & Free Conveyor System is used to transport truck frames from the assembly plant to the E-Coat Process building and from E-Coat to shipping.

Power & Free System

Automotive Frame Manufacturing

Multiple switch arrangement for the sorting of frames.

Power & Free System

Automotive Manufacturing Facility – Inline Vehicle Sequencing System

View of cross transfer conveyor with pop-up roller transfers to ASRS in-feed conveyors.

Power & Free System

Automotive Manufacturing Facility – Turntable, Transfer & Accumulation

Turntable, transfer and accumulation conveyors for transfers to and from ASRS system.

Power & Free System

Engine Dress & Delivery – Automotive Manufacturing Facility

Project includes Pedestal Slat Conveyor, Cranes, P&F (Power & Free) Rework & V.I.N. (Vehicle Identification Number) Making Station.

Flat Top Conveyor System

Flat Top Conveyor System

Heavy Truck Manufacturer - Final Trim & Inspection Line

System includes a Flat Top Conveyor as well as several Over & Under style In-Floor Towlines for transport of vehicles through various assembly operations.

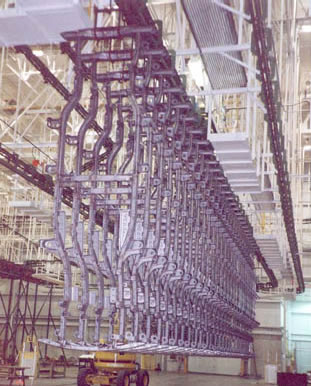

Inverted Power & Free System

Inverted Power & Free System

Parts Transfer Conveyor – Automotive Component Facility

Parts (not shown) are automatically transferred from Dual Strand Chain Oven Conveyors to P&F and then transferred to Unload/Paint Line Conveyor.

Metal Scrap Handling System

Metal Scrap Handling System

System with Slewing Discharge Chute Automotive Component Stamping Facility

System receives metal scrap from multiple stamping presses and automatically loads the scrap gondolas.

Mold Transfer System

Mold Transfer System

Mold Transfer Conveyor Systems

Partial system shown during in-house setup and test. Finished length of the system is 300 feet.